Booth facilities

3 Booths ( Three coat / Four coat system)

3 Booths ( Three coat / Four coat system)

1Booth ( Single coat / Two coat system)

Booth ( Size-14 Feet X16 Feet) Side draft cum center draft booth

Interior parts like bezel, Fascias, and exterior parts door handles, spoilers can be painted

Conveyorised paint shop

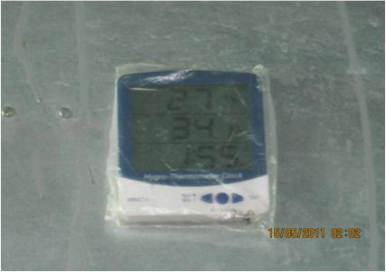

Average 0.5 m/s air velocity in the booth

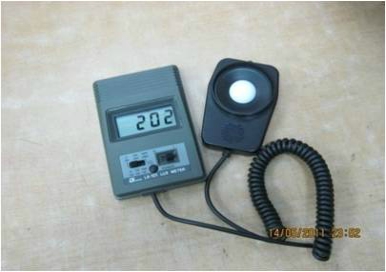

- Illumination 800 lux at painting height

- Total flooring covered with gratings & water to avoid dust contamination

- Conveyorised paint shop for booth & oven

Paint sludge removal system along with recirculation of water in the booth

- All operations are in the filtered air pressurized zone